Cloud-Hosted Quality Platform Integrating the Continuous Improvement Model for Industrial Construction

At Gray Construction, our No. 1 core value is: we put safety and quality of life first. Safety is of upmost importance to ensure everyone goes home at the end of the day in the same way they showed up. Quality works in tandem with safety and also fulfills our purpose of making a difference in people’s lives by creating unforgettable customer experiences and great projects. This means putting quality above schedule and just simply doing the right thing because it’s the right thing to do. Meeting industry standards is a big part of quality, but, at Gray, it’s more than industry standards, it’s meeting customers’ expectations as well.

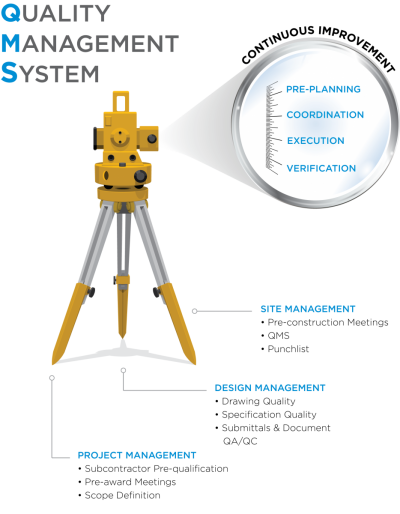

Reflecting back on nearly six decades of experience in the construction business, our quality management system (QMS) is a living, dynamic process that begins day one of the project. At its inception, site managers provided input on the critical quality issues they encountered on projects. These items were turned into checklists per division and kept in 3-ring binders. Through continuous improvement, Gray’s award-winning, cloud-hosted QMS platform evolved into a digital/mobile platform for quality auditing. It pulls data and enables regular check-ins for quality. The system also works in conjunction with our warranty tool to establish another layer of checkpoints and historical data. As the company has grown and projects continue to become more complex, Gray continues to apply the continuous improvement model to its quality approach.

In recent years, the quality industry has changed, largely due to smart manufacturing. Companies have become more complex, and therefore, their projects have naturally followed suit. What were previously “big box” projects are now advanced processing and packaging facilities, cold storage facilities, deep pits in close proximity to the ocean and a whole host of other variables adding further layers. As a result, these complex projects come with a lot of risk. Today, quality has evolved into a form of risk management to ensure the final product of the facilities meet and exceed the needs manufacturers.

The quality group at Gray has begun an internal training series to educate team members on trends and challenges ranging from concrete to windows that construction is experiencing within the industry. Additionally, we are working to be even more proactive regarding quality at every phase of construction, as well as continuing to support our trade partners in their quality control programs and teaming up with vocational schools to ensure the future of construction integrates quality into their programming.

To learn more about our approach to quality, visit our Quality hub.

- Category:

- Industry

- Opinion

- Construction

- Equipment

- Facility

- Pre-Construction

- Design

- Architecture

- Design Technology

- Specialized Services

- Digital

- Automation & Controls

- Advanced Automation

- Digital Transformation

- Production-First IT

- Engineering

- Civil/Building Engineering

- Mechanical/Electrical Engineering

- Process & Packaging Systems Engineering

- Equipment

- Fabrication

- Maintenance

- Skid Systems

- Planning

- Master Planning

- Front-end Services

- Strategy Consulting

- Commercial

- Distribution

- Food & Beverage

- Manufacturing

- Data Centers

Related News & Insights

Construction Safety: A Necessary Commitment

Projects

May 03, 2017Commercial, Construction

Gray Construction Team Members Named to Tilt-Up Concrete Association’s Young Professionals Collaborative

Corporate News

January 23, 2019Food & Beverage

Gray Project Receives Manufacturing Innovation Award

Corporate News, Industry

December 04, 2024