How Well Are Manufacturing and IT Leaders Collaborating?

When functional departments remain in silos, it’s hard for people to work together to achieve shared company goals. Manufacturing and IT divisions — and it’s telling that we still call them “divisions” — often have an uneasy relationship. Now two studies update us on IT’s struggle to be part of strategic planning and manufacturing’s problems with IT application reliability and downtime.

Rapid shifts of applications to the cloud, overburdened networks, and uncertain application reliability are challenges that make cross-functional teamwork more critical than ever.

When functional departments remain in silos, it’s hard for people to work together to achieve shared company goals. Manufacturing and IT divisions — and it’s telling that we still call them “divisions” — often have an uneasy relationship. Now two studies update us on IT’s struggle to be part of strategic planning and manufacturing’s problems with IT application reliability and downtime.

Business planning without IT involvement

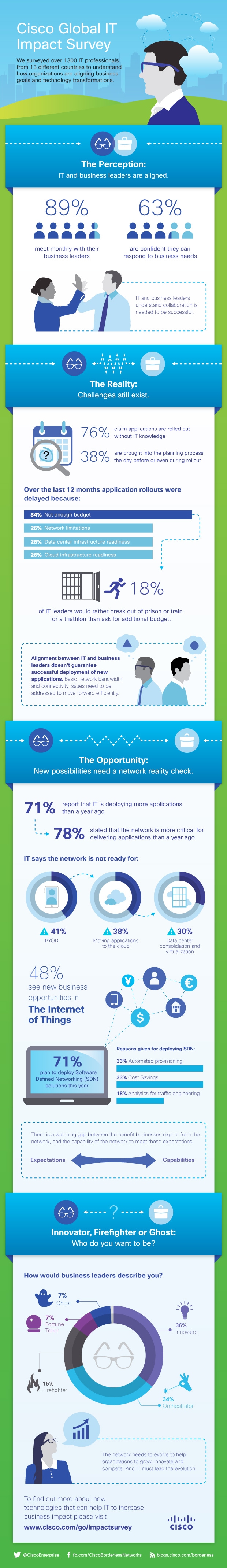

IT leaders feel left out of business operations decisions and planning, according to the 2013 Cisco Global IT Impact Survey of IT professionals. There is no lack of communication — 89% of IT leaders meet with business leaders once a month or more. Yet, on average, 25% feel that, when it comes to planning future business initiatives, IT has low visibility in the organization.

In fact, 78% even say business leaders sometimes or always work around IT, rolling out applications on their own. Even when IT leaders are brought into applications planning and deployment, 38% say they are brought into the process late, 21% of them saying “the day before rollout.”

Cisco Global IT Impact Survey

Cisco Global IT Impact Survey

One effect of the planning gap is that business leaders may underestimate the readiness of network infrastructure to support new applications or to handle the rush to move them to the cloud. 37% of IT leaders believe their systems may not be able to support some planned business initiatives. A whopping 78% of IT leaders say that their networks are overburdened now, adversely impacting web, file service, and email performance. As well as having concerns about network performance, IT leaders are worried about ensuring data security and the availability and reliability of external systems.

Business leaders may not spend much time thinking about the network’s physical wires, switches, and device layers, but IT leaders do. Software network management systems for more flexible control — software defined networking (SDN) — are being touted as a solution to the need for reconfiguring physical connections when network usage is changed. Almost three out of four companies in the survey will deploy SDN in the next year. Business leaders are signing off on SDN because of promised benefits such as fast scalability, custom applications, and cost savings. We’ve all seen what can happen when IT’s Next Big Thing is hastily introduced: snarled processes and frustrated users. In order to implement SDN strategically, IT and business leaders will need to collaborate better than ever.

It’s pretty obvious that employees want to bring their personal mobile devices to work. That makes IT leaders nervous — 41% of them feel their companies have not thought through either the positive or the negative implications of this avalanche of change. The use of mobile devices raises a new crop of security issues. On top of the problems of ensuring the availability and reliability of network and cloud applications, deploying versions for new mobile applications makes things even more complicated.

The view from manufacturing’s side of the wall

Most manufacturing managers say they are satisfied with manufacturing application performance, as reported in a Penton Research survey. Yet there is a difference between companies using IT applications in the virtual world — the cloud — than those staying in the old one. Of the 16% of respondents who do run systems in a virtualized environment, two out of three are extremely satisfied or satisfied (68% vs. 51%) with IT application availability and reliability. Only half of the 84% who haven’t advanced to the cloud say the same.

System downtime is a profit-killer. In the first four months of 2013, more than one in four respondents experienced manufacturing application downtime events. Manufacturing operations were hit with an average of seven downtime incidents in the past year from failures of IT application availability, at a cost of nearly $17,000 each time. Larger companies have been struck by more of them, and at a higher cost per incident.

More companies are implementing high availability manufacturing IT strategies or solutions. The one in three respondents that report they now have one are more likely to be extremely satisfied with application availability (17% say so) than those who don’t (5%). For most, a high availability strategy means some sort of backup method. At larger companies, those with annual revenues exceeding $1 billion, 26% use built-in high availability functions, 23% use fault tolerant servers, 16% use windows clustering and 9% use high availability software. But these numbers show that the methods being used are not yet producing highly satisfying system performance, and that the majority of companies have yet to come up with a high availability strategy at all.

Get IT together

The relative performance advantage in companies with high availability strategies should be a lesson on the benefits of teamwork between manufacturing and IT managers. Where IT management is still excluded from business planning and operations, there is a lot of work to be done. In these companies, senior management may not be providing the best leadership in unifying their teams and developing a culture of collaboration. When they don’t bring the two together, leaders are sacrificing both operational performance and the long-term competitiveness of their companies.

Karen Wilhelm has worked in the manufacturing industry for 25 years, and blogs at Lean Reflections, which has been named as one of the top ten lean blogs on the web.

- Category:

- Manufacturing

Some opinions expressed in this article may be those of a contributing author and not necessarily Gray.

Related News & Insights

Advanced Technology, Automation & Controls

Four Use Cases for AI's Growing Role in Manufacturing

Industry

November 25, 2024Data Centers

Gray Expands Reach with Dallas Office

Corporate News

November 14, 2024Manufacturing, Construction

The Evolving Role of Electric Vehicles in Sustainable Construction & Design

Industry

October 18, 2024