Which Technologies are Taking Construction Jobsite Safety to the Next Level

It’s no secret that the construction industry is risky business. Even with big improvements in safety regulations and training over the last decade, the U.S. Bureau of Labor Statistics indicates that one in five work-related deaths occurs in the construction industry. Injuries on the job also lead to higher insurance and administrative costs, project delays and reduced productivity.

Every construction company wants its workers to return home safely at the end of the day. This is becoming easier to achieve with innovative new products that improve the safety of day-to-day operations. Below are just a few ways technology is enabling construction companies to design safer job sites, improve communication and reduce costly injuries and delays.

1. Smart wearables

Smart wearables such as watches, glasses, and other wearable products can improve construction safety. DAQRI, a Los Angeles-based company, has developed a smart helmet that uses 4D augmented reality technology to capture and share information related to safety. A transparent visor serves as a heads-up display that allows work instructions to be seen through the helmet in the context of the job being done.

2. Drones

Drones are used to inspect job sites and gather real-time data on job progress. “This reduces the need for superintendents and safety directors to physically walk job sites,” Ralph Barszcz, safety director for Leopardo Companies, states in an article on REJournals.com. Some larger drones, he notes, are also utilized to move heavy materials, preventing injuries that could possibly result if the work was done manually.

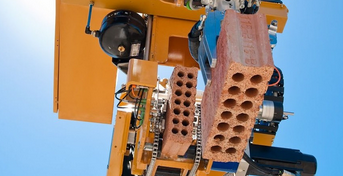

3. Robots

Robots have also been designed to move heavy materials on the job site—and can even do some of the construction. Fastbrick Robotics has developed an automated 3D brick-and-block-laying system. “The robot can read designs, load, cut, rotate, and place up to 1,000 bricks per hour—this is a pace of one complete house in less than two days,” says Barszcz. “This also reduces or even eliminates injuries that could result from manually performing bricklaying and masonry trades.”

4. Smart devices

There are plenty of ways smart devices improve contractor safety on the job and connect the field and office for real-time decision-making. For example, Google recently released Project Tango, a mobile device that relies on computer vision, image processing, and sensors to create 3D models that can be instantly shared with project managers and other team members. This also means less time is spent taking measurements and navigating potentially hazardous job sites.

5. Software and apps

Thanks to virtual design and construction (VDC), modeling software can be designed to create highly detailed, 3D maps and plans of a site before construction starts, allowing teams to identify and mitigate potential safety risks. Interesting construction apps include SafetyCulture’s iAuditor app, which allows real-time collection and analysis of data required for managing jobsite safety and quality. SK Solutions, a Dubai-based software firm, has created an anti-collision software system that monitors the position, movement, weight, inertia, wind speed, and direction of construction site equipment such as tower cranes. The data can be viewed on dashboards and mobile devices, while sensors may also be attached to on-site workers for greater insights.

As enabling as this technology is…

It’s important that workers not become too dependent on technology in the field. Barriers to communication and planning are overcome when project teams have the ability to share information and interact in real time. However, apps and devices also depend on network and Internet connections, as well as access to the cloud; if technology fails, like losing connectivity, employees can potentially be left without the suite of tools they’ve come to rely on.

“Proper training, discipline, and an ability to adapt without complete dependency will be crucial to the success of any safety program utilizing technology,” adds Barszcz. “The net benefit that contractors and their clients realize is threefold: better communication, great efficiency, as well as an undeniably safer project site.”

Mark Crawford is a Madison, Wisconsin-based freelance writer who specializes in business, science, technology, and manufacturing.

- Category:

- Industry

Some opinions expressed in this article may be those of a contributing author and not necessarily Gray.