The Correlation Between Lean Managers and Coaches

There is a growing movement globally to think of managers as coaches. It is very visible in the lean movement, and former coaches of national sports teams have found themselves in consulting roles to leaders of companies seeking to become lean enterprises. It turns out they have a lot to offer because the model of a lean leader has much in common with the model of a sports coach.

The two most basic prerequisites for being a good sports coach are that you know the game and that you understand where the players are. To really know the game, for starters, an effective coach must be able to watch someone throw the ball, defend the goal, block out an attacking defender and still be able to critically assess what is happening compared to what should be happening. Secondly, coaches need to be where the players are in order to lead the practices, set up opportunities for skill development, and watch carefully to give critical feedback.

In lean, we now call this managing from the gemba – the place where the work is being done or the customers are using the product. A lean manager should get out of their office and out of staff meetings and be where the game is being played for their core value streams. Sounds simple enough, but it is often remarkably difficult for managers to pull themselves away from meetings and running from fire to fire.

Getting managers to go to the gemba sounds a lot like what Peters and Waterman called “management by walking around” in their classic In Search of Excellence. What managers found was that they built relationships by walking around, but it was not clear what they should be doing. Trained for decades in command and control management, they naturally gravitated toward telling people things. There are always plenty of opportunities in any workplace to notice deviations from standard operating procedures. Things are out of place, people are not working at their machine or desks, there seems to be a lot of wasteful walking around, and so on. But, the natural tendency is to start questioning these wasteful activities. Why is that person just standing around? Why is all this material piled up? In an ideal world perhaps everything would be perfect, but in reality there are always far too many problems like this to fix.

Rather than sending managers blindly to the floor to seek out obvious problems, there is another approach that’s better – focusing limited time for improvement on what really matters to the business. This requires a direct connection between company strategic challenge, an understanding of what needs to change in the operation to achieve that challenge, and a systematic process for improving toward the challenging objective. One company, Merillat, a kitchen cabinet manufacturer, defined its strategic challenge as “a kitchen at a time.” Then Vice President, Keith Allman (now CEO), saw the most critical need of the company as getting their primary customers – builders – everything they need to build an entire kitchen complete, perfect quality, on time. This would give the company a strategic advantage. Allman, a lean veteran, then led a process of identifying where to start in developing this capability, and what leaders he would need to coach to become lean leaders. By starting small in final assembly, Allman was able to lead the company through an enterprise-wide change.

For a manager to be effective as a coach, he or she needs, at minimum:

- One student (learner) at a time

- A vision for ideal state of lean leader (What is excellence?)

- Understanding of the student (What is the current ability level?)

- Defined improvement process to teach (What am I trying to teach and how?)

- Actual improvement project to coach through (Learn by doing on a focused project with clear objectives that matter)

- Defined coaching process (Short interval feedback and reflection)

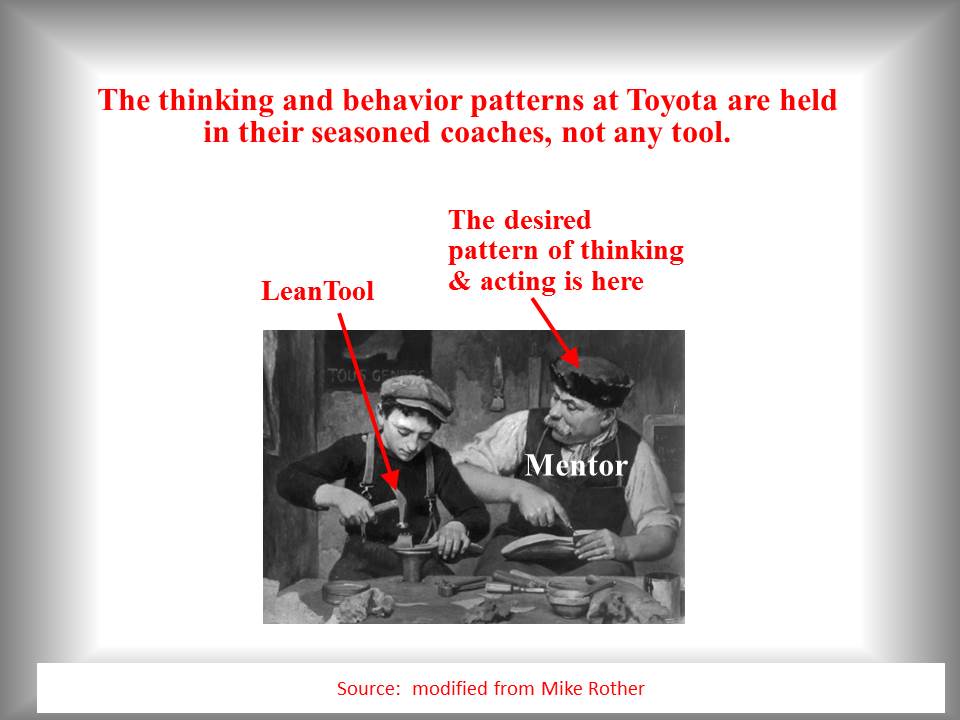

Figure 1: More Than Teaching Tools

Figure 1: More Than Teaching Tools

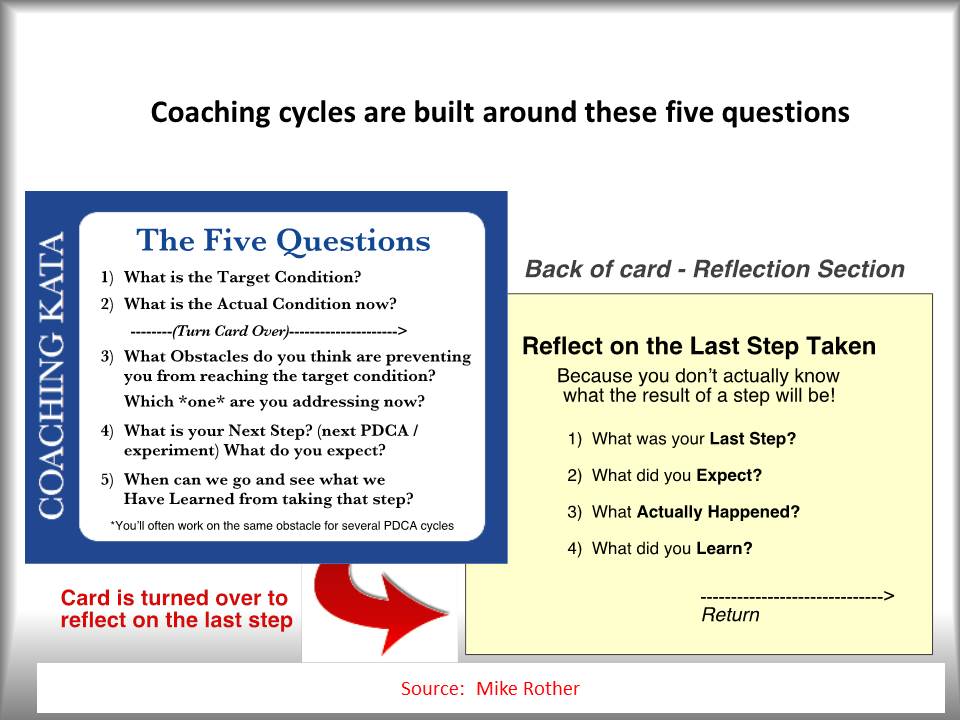

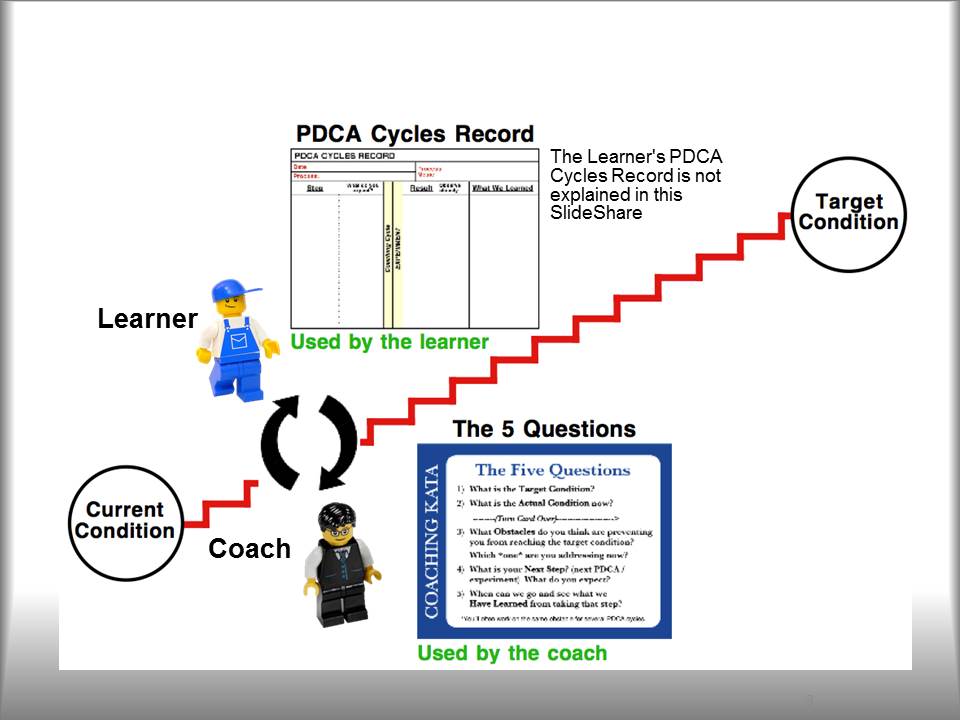

What is often confusing about lean is the misunderstanding that the challenge is to understand the most pressing problems or apply the tools to fix problems. Like master craftsmen, the teacher is much more interested in what the student is thinking, doing, and learning while using the tools than the specific tools or projects (see Figure 1). Coaching any complex skill is a step by step process. Toyota Kata breaks the coaching process into steps and allows the learner to practice every day individual pieces of the overall improvement process guided by both long-term business needs and very immediate short-term targets a few weeks out. The coach also has a kata (routine) including asking questions designed to find out what the student understands about the direction, current process, near-term target, and what is being learned from each small attempt at improvement to practice so there are no surprises (see Figure 2). Learning any complex skill requires daily practice and the role of the coach is to give corrective feedback and keep the learner on track (see Figure 3).

Figure 2: The Five Coaching Kata Questions

Figure 2: The Five Coaching Kata Questions

Figure 3: Coach and learner meet for at least one coaching cycle every day related to learner’s target condition

Figure 3: Coach and learner meet for at least one coaching cycle every day related to learner’s target condition

At the end of the day, characteristics of a good leader as coach include:

- Highly skilled in philosophy and methods of improvement (Credible)

- Keen observer of people: technical and interpersonal skills

- Listens more than talks

- Pulls best from student instead of pushing knowledge into head

- Provides frequent, specific feedback for small intervals of student work

- Truly cares about student’s learning

- Respectful of people

- Aims for mutual development and trust

If you’d like to learn more on this topic, watch this presentation:

Dr. Jeffrey Liker is professor of industrial and operations engineering at the University of Michigan and author of The Toyota Way. He leads Liker Lean Advisors, LLC and his latest book (with Gary Convis) is The Toyota Way to Lean Leadership.

- Category:

- Industry

- Manufacturing

Some opinions expressed in this article may be those of a contributing author and not necessarily Gray.

Related News & Insights

Advanced Technology, Automation & Controls

Four Use Cases for AI's Growing Role in Manufacturing

Industry

November 25, 2024Data Centers

Gray Expands Reach with Dallas Office

Corporate News

November 14, 2024Manufacturing, Construction

The Evolving Role of Electric Vehicles in Sustainable Construction & Design

Industry

October 18, 2024