Regulation, Healthcare & Other Barriers Facing Today's Manufacturers

For manufacturers in the United States, recent surges in demand have given rise to a newfound optimism. Consumer confidence is up, the economy is stabilizing, and government uncertainty has been somewhat diminished. But, despite this optimism, obstacles still lie in the path of sustainable growth for our industry. Heavy government regulation, the unrelenting issue of attracting skilled labor, and new costs associated with the Affordable Care Act are among the issues continuing to burden manufacturers and impede competitiveness.

For manufacturers in the United States, recent surges in demand have given rise to a newfound optimism. Consumer confidence is up, the economy is stabilizing, and government uncertainty has been somewhat diminished. But, despite this optimism, obstacles still lie in the path of sustainable growth for our industry. Heavy government regulation, the unrelenting issue of attracting skilled labor, and new costs associated with the Affordable Care Act are among the issues continuing to burden manufacturers and impede competitiveness.

The Regulatory Environment

Manufacturers support reasonable and balanced regulations, but over the past few decades, the regulatory system in the United States has gone off track. The Manufacturers Alliance for Productivity and Innovation looked at the past three decades and counted some 2,300 regulations that have been imposed on manufacturers.

It’s hard to identify a specific type of regulation that is hurting manufacturing growth because it’s being hit from all sides. The Securities and Exchange Commission, Health and Human Services, the Occupational Safety and Health Administration, the National Labor Relations Board and others all make policy decisions that affect manufacturers.

But for many manufacturers, the biggest concern is the Environmental Protection Agency (EPA). The National Association of Manufacturers (NAM) commissioned a study of six major EPA regulations that concluded the rules could cost manufacturers more than $100 billion annually and lead to the loss of 2 million jobs.

The EPA’s impact, however, goes beyond the burdens it imposes directly on manufacturers. The EPA has gone from a government bureau intended to safeguard our air and water to an agency that is basically setting the energy policy of the United States.

The EPA’s recent rule on carbon dioxide emissions from coal- and gas-fired power plants—the so-called New Source Performance Standards—starts the U.S. down a dangerous path. The rule would effectively ban the construction of any new power plant powered by coal, foreclosing the use of an energy source that today provides nearly 40 percent of our electricity.

Manufacturers support an “all-of-the-above” energy plan because it provides price stability and energy security, both of which are critical to competitiveness. Manufacturers use one-third of the energy consumed in the U.S., so any disruption in supply or price shock has a major impact on the sector.

Regulators won’t stop at coal. The EPA’s next move will be to regulate not just new, but also existing power plants. Then it will move on to other industries, ultimately imposing carbon emissions limits directly on manufacturers. Eventually, unelected bureaucrats will regulate the entire economy.

What manufacturers need is for agencies to stop overreaching—clearly, Congress never intended to give the EPA such broad authority—and do a better job of weighing the costs of a regulation against its benefits.

The Burgeoning Workforce Development Issue

Eighty-two percent of manufacturers report that they have jobs going unfilled because they can’t find workers with the right skills. Eliminating the skills gap is a priority for manufacturers, and the NAM is devoting significant resources to this problem. In fact, we recently created a task force to help craft solutions that can be effective across industry sectors.

In addition, The Manufacturing Institute, which is an arm of the NAM, has a number of initiatives aimed at building a workforce that meets the needs of 21st-century manufacturing. At the heart of these efforts is a skills-certification program, which allows American workers to receive a portable credential that demonstrates to manufacturers the skills they possess.

One exciting program that uses the skills-certification process is Get Skills to Work, which helps to match the skills veterans received in the military to skills coveted by manufacturers. If veterans need to learn new skills, the Institute can help them earn those credentials through partnerships with community colleges and other educational institutions. A number of manufacturers are part of this effort.

The NAM is also focused on manufacturers’ future needs. The manufacturing workforce is aging, with many workers nearing retirement. To attract the next generation of manufacturers, the STEP Ahead Initiative seeks to bring women into the manufacturing workforce and the Dream It. Do It. campaign shows students the many career options manufacturing offers.

The Impact of Health Care Reform

When President Obama sought to lower health care costs and increase access to care, manufacturers shared that aspiration. Unfortunately, the Affordable Care Act won’t achieve those objectives. It will raise costs and limit flexibility for employers and employees.

Manufacturers already provide generous health care benefits—some 97 percent of manufacturers offer health coverage to their employees. The health care law threatens our ability to provide these benefits by forcing us into a one-size-fits-all, government-blessed system. Even worse, it doesn’t look like it will do anything to rein in health care costs. The law actually puts manufacturers and our employees in a worse position than the one we are in now. It makes the problem—how to provide affordable health coverage to our employees—worse.

As for future industry growth, rising health care costs could definitely have an impact. But perhaps the worst consequence will be that some employers will make hiring decisions based on the Affordable Care Act instead of the needs of their business.

Other Barriers to U.S. Manufacturing Growth

Currently, it is 20 percent more expensive to manufacture in the U.S. than compared to our major trading partners. Issues like regulations and lawsuit abuse contribute to this cost differential, but the largest driver is taxes.

Our uncompetitive tax system has an impact on manufacturers of all sizes. At the corporate level, manufacturers face a top rate of 35 percent—the highest among developed economies. Moreover, the U.S. is one of the few countries that taxes worldwide income. Manufacturers need a globally competitive tax system that encourages investment.

Small and medium-sized manufacturers face challenges of their own. In fact, two-thirds of manufacturers pay taxes at individual rates because they are organized as “flow-through” entities, like an S-corporation. Some of these businesses were hit with a tax increase at the beginning of this year and now face a tax rate of up to almost 40 percent.

The NAM Growth Agenda

The NAM Growth Agenda

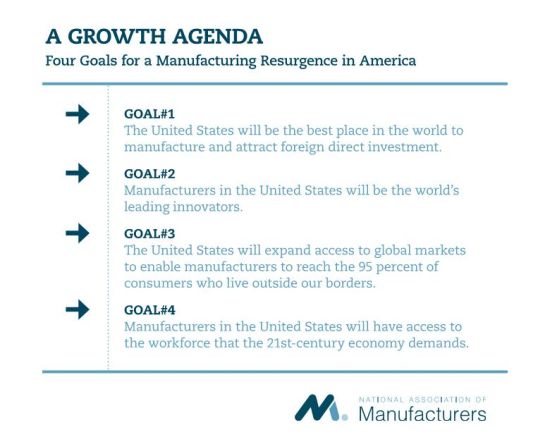

Manufacturers have many other concerns—but we have solutions too. The NAM has a “Growth Agenda,” which lays out a roadmap for strengthening manufacturing and our economy. It’s a blueprint of manufacturers’ policy priorities and a guide for lawmakers looking for a pro-growth strategy. The document is available at the NAM website, www.nam.org.

Jay Timmons is president and CEO of the National Association of Manufacturers (NAM), the largest manufacturing association in the United States representing small and large manufacturers in every industrial sector. He became NAM president in January 2011. Mr. Timmons is a leading advocate for the nearly 12 million men and women who make things in America, educating the public and policymakers on issues that affect this critical sector of the U.S. economy. He promotes a broad-based agenda to strengthen U.S. competitiveness and bring about a manufacturing renaissance.

- Category:

- GrayWay

- Industry

- Manufacturing

Some opinions expressed in this article may be those of a contributing author and not necessarily Gray.

Related News & Insights

Advanced Technology, Automation & Controls

Four Use Cases for AI's Growing Role in Manufacturing

Industry

November 25, 2024Data Centers

Gray Expands Reach with Dallas Office

Corporate News

November 14, 2024Manufacturing, Construction

The Evolving Role of Electric Vehicles in Sustainable Construction & Design

Industry

October 18, 2024