GE's Innovation Explosion to Take Manufacturing into the Future

One of the great-grandfathers of manufacturing, century-old GE, is bristling with innovations in innovation: crowdsourcing, “makers” spaces, open patents, and lean startup thinking. Wisely, old and venerable GE has accelerated its regeneration by partnering with young leaders and companies.

Eric Ries, Author of The Lean Startup

Eric Ries, Author of The Lean Startup

GE started by seeking out Eric Ries, serial entrepreneur and chief advocate for the Lean Startup movement. Ries is helping GE develop its FastWorks program, defined as “a set of tools and behaviors designed to deliver better outcomes for customers faster.”

Rather than one focused innovation process, GE is simultaneously setting several loose, accelerating learning by tapping into creative communities and cloud-based innovation platforms. At early stages, each avenue to innovation can be tested and evaluated, and lessons learned can be applied. That’s the precept of “fail early and often.” The least likely to succeed can be ended before significant resources are committed. Seeing the arcs and outcomes of the various ventures will refine the next approaches.

In addition to faster paths to new products, GE wants to inculcate a culture of testing and learning throughout the organization. Last year, 80 FastWorks coaches reached 1,000 GE executives around the world, as 100 Lean Startup FastWorks projects launched. This year the coaches will fan out and help 5,000 executives get on board. The plan is to launch hundreds more projects and transform manufacturing.

What are some of GE’s innovation experiments?

Garthen Leslie, Inventor of the Aros

Garthen Leslie, Inventor of the Aros

GE already has a proof of concept for global collaborative problem solving. It went to the open engineering platform GrabCAD for a better titanium alloy bracket design that could be 3D printed. The winning design from an engineer in Indonesia shaved 84% off the original design’s weight, and netting the designer a $20,000 prize. What would it have cost GE to redesign the part through its old engineering process and knowledge base?

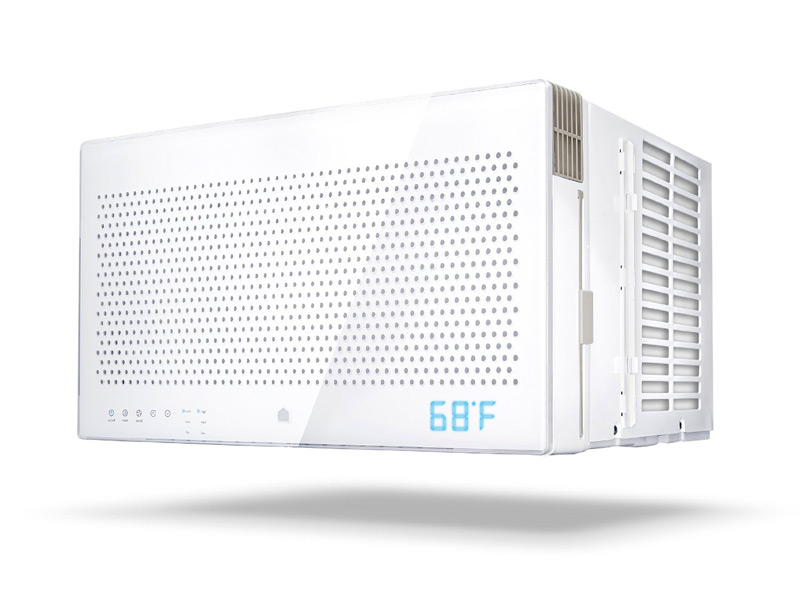

Quirky is an online community of more 2,000 designers and enthusiasts. Entrepreneur Garthen Leslie asked for help developing a smarter air conditioner that could be controlled over the internet using a smartphone, and that can learn from your usage patterns. Teaming up with Quirky’s community members, GE contributed a patent library and engineering knowledge. The resulting Quirky + GE Aros unit is now on sale at Amazon.

Quirky + GE Smart Window Air Conditioner

Quirky + GE Smart Window Air Conditioner

In in my “Manufacturing Innovation in Digital Workspaces” blog post from last year, I highlight LocalMotors. Now, LocalMotors and GE are launching a project called FirstBuild. It will use the LocalMotors cloud platform, community, and micro-factory model to create, prototype, and build imaginative kitchen appliances for “the future of cooking.” Engineers, fabricators, designers and tinkerers from anywhere on the web will virtually meet up with GE experts. The first microfactory is about to be built on the campus of the University of Louisville, giving students the opportunity for hands-on participation and the pioneering of new manufacturing models.

GE Garages are open innovation “Maker” movement projects with hackathon-like events. The GE Garages project rounds up several of GE’s innovation partners including FirstBuild, Quirky, the crowdfunding source indiegogo, 3D design software provider Autodesk, inventables for digital fabrication resources, makers movement leader Make:, MakerBot, Proto Labs, SparkFun Electronics, TechShop consultant networks, and Arduino. Although the calendar has not yet been published, there will be a GE Garages road trip this year.

With the GrabCAD, Quirky, FirstBuild, GE Garages ventures, and potentially hundreds more from the FastWorks project, GE is taking a lean startup approach to lean startup ventures. It’s a lean product development approach applied to developing lean product development capabilities.

Of course, GE is only coming home to its beginnings. Its laboratory of strategies is not so different from founder Thomas Edison’s laboratory of invention. Edison’s scientific process of theorize, experiment, fail, learn, improve, and invent led to an unprecedented portfolio of innovation.

This new explosion of trials will be fun to watch. Other companies need to do more than watch, however. They need to be unleashing their own innovators and support experimentation without rigid payback schedules. They need to reach out to customers and digital communities, without walling off all their intellectual property. They need to find their own paths to faster, smarter product development strategies. More value, less waste, faster cycle time — just what we’re looking for in lean business management.

Further reading: Brad Power’s “How GE Applies Lean Startup Practices” in the HBR Blog and Liz Stinson’s “How GE Plans to Act Like a Startup and Crowdsource Great Ideas” in Wired. They each share valuable insights and examples.

Karen Wilhelm has worked in the manufacturing industry for 25 years, and blogs at Lean Reflections, which has been named as one of the top ten lean blogs on the web.

Images courtesy of The Lean Startup & GE’s press center.

- Category:

- Manufacturing

Some opinions expressed in this article may be those of a contributing author and not necessarily Gray.

Related News & Insights

Advanced Technology, Automation & Controls

Four Use Cases for AI's Growing Role in Manufacturing

Industry

November 25, 2024Data Centers

Gray Expands Reach with Dallas Office

Corporate News

November 14, 2024Manufacturing, Construction

The Evolving Role of Electric Vehicles in Sustainable Construction & Design

Industry

October 18, 2024