Food Manufacturing Plants Brace for Change as Safety Modernization Act Takes Form

The FDA is reforming what many believe are antiquated food safety laws with the development of the Food Safety Modernization Act (FSMA). The goal of this reform is to shift the focus from attempting to control contaminants in the U.S. food supply to preventing contamination altogether.

Doing business in a stringent regulatory environment is nothing new to today’s food processors, especially in the meat and poultry industry. The U.S. Department of Agriculture (USDA) has been enforcing its ever-so-strict food quality and safety dogma for decades and such oversight is entrenched in the everyday practices of meat and poultry businesses. Likewise, all other food and beverage businesses have long been regulated by the Food and Drug Administration’s (FDA) rigid quality and safety programs.

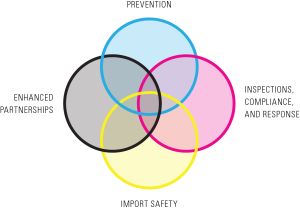

Themes of the Food Safety Modernization Act (Source: FDA)

Themes of the Food Safety Modernization Act (Source: FDA)

But now, the FDA is reforming what many believe are antiquated food safety laws with the development of the Food Safety Modernization Act (FSMA), signed into law by President Obama in January of 2011. The goal of this reform is to shift the focus from attempting to control contaminants in the U.S. food supply to preventing contamination altogether. While it may be too soon to tell how the FSMA will impact the food and beverage industry, some experts believe this reform will mean sweeping changes to traditional food handling and processing practices.

“Any food plant or manufacturer that is regulated by the FDA is going to be required to have a preventative control plan,” explained Hilary Thesmar, vice president of food safety programs for the Food Marketing Institute. “So, they have to implement basically a food safety plan that’s going to prevent food safety problems from occurring and to identify what hazards could occur and try to control those hazards.”

Food safety experts have varying opinions on how this might affect business-as-usual for the nation’s food processors. Allen Merritt, managing director for his food safety consultant group, Allen & Associates Consulting, thinks that the biggest impact will be in the area of inspection.

“I think what is going to happen is the inspection intensity is going to change,” Merritt explained. “And in meat and poultry, if the local inspector doesn’t think your plant’s clean, you don’t start up today. That kind of activity has never been experienced by the rest of the industry, unless there is a severe problem.”

Others doubt the government’s ability to fund such a program. David Baker is a food safety consultant who has worked with some of the top food processors in the nation and knows a little something about putting together effective food safety programs. Baker says while the USDA has the funding to provide round-the-clock inspectors on-site in the nation’s meat and poultry plants, it would be a huge jump for the FDA to follow suit.

“The balancing point is where the economy goes and whether the government will have enough money to implement the programs that they’ve foreseen,” said Baker. “These types of programs are very expensive. And, whether they’ll actually come up with a program that is aggressive enough to charge companies with the actual costs of inspection is also an unknown.”

The issue of increasing inspection costs is being addressed by the FDA, however. In January of 2012, the FDA released a one-year progress report noting the more significant FSMA developments. The report states the FDA helped fund and establish the Produce Safety Alliance and the Food Safety Preventive Controls Alliance “to help industry, especially small and very small firms, to comply with the requirements.”

Other highlights in the report include a new “consumer-friendly” web search for recalls on the FDA website; a new joint strategy with the Department of Homeland to help identify and prevent smuggled foods from entering the U.S. and posing a threat to national security and consumer safety; and new pilot projects to be implemented by the Institute of Food Technologists (IFT) aimed at enhancing the ability to trace products responsible for foodborne illness outbreaks.

In the area of inspection, the FDA reported that it has already met the FSMA mandate for foreign food safety inspections and, at its current pace, is set up well to meet the 5-year inspection frequency mandate for high-risk domestic food facilities.

To access the complete FSMA One-Year Progress Report, visit the FDA’s website at www.fda.gov/Food/GuidanceRegulation/FSMA/

- Category:

- GrayWay

Some opinions expressed in this article may be those of a contributing author and not necessarily Gray.

Related News & Insights

Food & Beverage

Gray Project Receives Manufacturing Innovation Award

Corporate News, Industry

December 04, 2024NexGen Spotlight: In Pursuit of Excellence

Stories

Advanced Technology, Automation & Controls

Four Use Cases for AI's Growing Role in Manufacturing

Industry

November 25, 2024