Food Processing on the Rise, Thanks to Technology & Innovation

Throughout the past several years, manufacturing across the U.S. has experienced a tremendous surge in growth. Apart from the data that is backing this manufacturing revival, as it’s being called, Gray Construction has witnessed this in our own customer trends. The food and beverage market is one specific market that is driving this resurgence.

Throughout the past several years, manufacturing across the U.S. has experienced a tremendous surge in growth. Apart from the data that is backing this manufacturing revival, as it’s being called, Gray Construction has witnessed this in our own customer trends. The food and beverage market is one specific market that is driving this resurgence.

Why is food manufacturing on the rise?

Although the industry has always experienced mergers and acquisitions, the M&A report from The Food Institute shows steady and increasing growth. This year alone, we’ve seen brands such as Tyson Foods and Hillshire Brands merge as well as Mars, Inc.’s acquisition of Proctor & Gamble’s pet food business.

Other food manufacturers are expanding in order to be closer to their customers and reach new and growing demands. For instance, Champion Petfoods, a Canadian-based company, is bringing a new kitchen and distribution facility to the U.S. to further its BAFRINO mandate of Biologically Appropriate, Fresh Regional Ingredients, Never Outsourced foods to a growing market.

For other food and beverage manufacturers like Keurig Green Mountain, the reason for growth is to introduce new products. In June, the company announced it would open a facility in Georgia to manufacture a new system called Keurig Cold. The Keurig Hot Brewing System with its ever popular K-Cups has enjoyed large success, making the company hopeful its new cold system will do the same.

After acquiring Chicago-based Wrigley in 2008, Mars, Inc. announced earlier this year that it would expand the existing manufacturing plant in Illinois to add the production of Skittles as a result of increasing sales.

The other reason for growth in the food industry is due to the fact that, as consumers have become more conscientious of what they put into their bodies, it has created more opportunities for food processors. Consumers want organic, healthy options for themselves and their pets, and the food industry has answered with new products to meet this growing trend.

Trends Influencing Food Processing

As this growth has taken off, trends in the manufacturing industry have helped spur development as well. Technology and innovation top this list of trends making a difference. We all readily recognize the difference that tech advances such as mobile access has made in our personal lives, but these same factors are changing the future of food processing too.

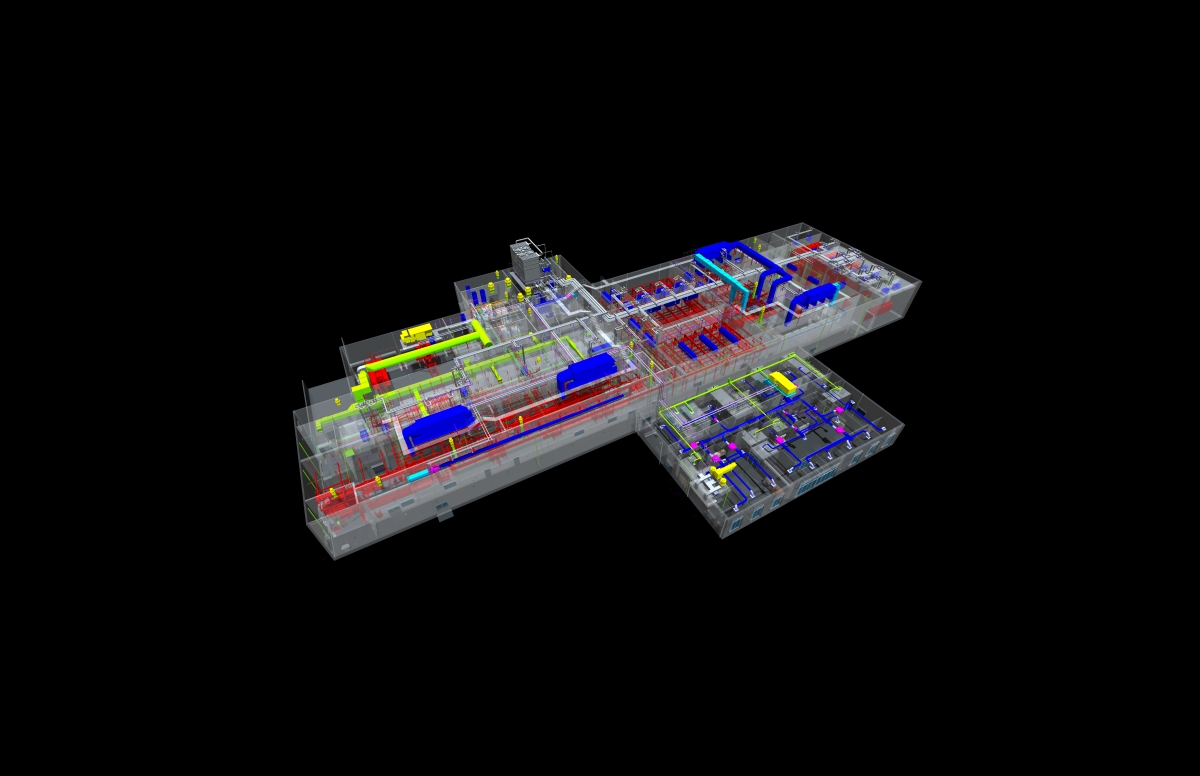

Building Information Modeling (BIM) is one such tool that’s being used to make a difference in how a food manufacturing facility is constructed. BIM has allowed flat and representational drawings to be replaced with a multi-dimensional, digital database illustrating how the building will look once complete. The fascinating part of BIM is that it allows users to see potential issues before they happen. This not only helps reduce change orders, but it also helps detect and avoid greater problems down the road.

3D printing, or additive manufacturing, is another advancement that has exploded within the manufacturing space. Apart from the benefits that occur on the assembly line and during the actual manufacturing process, 3D printing adds value before the building is constructed as well. In this way, construction firms are able to “build” the facility in the early phases of communication with the manufacturer to not only discover possible issues and make engineering and architectural adjustments, but to also better visualize how the facility will look.

Another new innovative technological trend that is growing in popularity is the use of Virtual Reality (VR). Like some of the other new advances, VR is being used in many applications for personal usage, but it also has a place in manufacturing and construction. For instance, Gray has recently started using Oculus Rift VR Goggles to allow our customers to “step into their facility” before it’s even built. Though the product is still in Beta, the usage is already impacting how manufacturing facilities are being designed and built. By providing a fully immersive experience for manufacturers, the quality and accuracy of the virtual environment provide an unprecedented understanding of what a facility will be.

When these types of elements are integrated into the design-build process of a food and beverage facility, it allows for the manufacturer to have more control over maintaining safety goals, preventing costly updates and maintenance issues down the road, and ultimately, satisfying the consumer with end products.

Join Gray at the International Production & Processing Expo (IPPE), the trade show representing an entire chain of protein production and processing, on January 27-29, 2015, in Atlanta, Ga., to learn more about how Gray’s tools and technology help food and beverage manufacturers reach their customers. On January 28th, 2015, experience first-hand our Gray Goggles at Booth #B7084 in Hall B to see how your next facility could be visualized before it’s ever built.

Some opinions expressed in this article may be those of a contributing author and not necessarily Gray.

Related News & Insights

Food and Beverage

The Science & Strategy Behind Cold Storage Facility Design

Stories, Industry

December 23, 2025Construction

Design-Build and Self-Perform: the Perfect Pairing

Industry, Opinion

December 01, 2025Food and Beverage

What's Driving the Growth of the Protein Segment?

Industry, Opinion

October 31, 2025