Is it the third industrial manufacturing revolution, a hot spot in your investment portfolio, or hype? The tech press is screaming about 3D printing:

Here’s a Tiny Printer for Your Smartphone

3D-Printable Guns Face Federal Ban

Bond’s 3D-Printed Aston Martin Makes ‘Skyfall’ Debut

3D Printer Breaks Kickstarter Tech Funding Record

If it’s a revolution, it’s been a slow one—30 years in the making. It was in 1986 that stereolithography (STL) was patented by Charles Hull. Using CAD data, a laser solidified a thin layer of plastic on the surface of a vat of liquid photopolymer plastic resin, continually adding layers until an object was built. The code that transformed CAD data to the .STL (standard tessellation language) file format that controls the laser may actually have been his greater achievement.

In 1989, Carl Deckard patented Selective Laser Sintering (SLS). His idea was to have a laser melt—sinter—a powder in a box, building an object layer by layer. SLS used plastic powders at first, but powdered metal was soon being sintered to make short-run molds or parts.

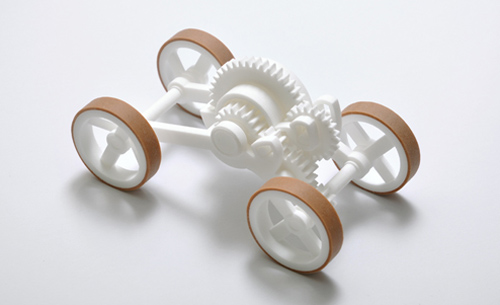

At the same time as Deckard was developing SLS, Scott and Lisa Crump came up with another competing technology: Fused Deposition Modeling (FDM). It builds a part using layers of extruded thermoplastic resin. FDM is now used to produce functional prototypes for testing parts in real-life use, as well as tooling or low-volume “direct digital manufacturing” production.

These additive manufacturing technologies made astounding changes to product design and development over the next decades. Yet the professional-grade machines are large, expensive, and take specialized skills to program and operate.

Watch 3D Systems’ Z Corp replicate a wrench on a 3D printer

That changed when smaller machines were developed. Once devices costing less than $10,000 came on the market in 2009, it didn’t take long for the technology to spread from engineering and design offices to basement and garage workshops.

3D printing for the consumer is the next front. Lower prices, cloud-based uses of the technology, 3D printing services at office supply stores, and design-your-own products on Amazon are all emerging realities. “Democratizing” additive manufacturing has become a business strategy.

Plastic extrusion 3D printers and printer kits can now be found for as low as $1,500. An online venture launched in 2012 allows the average person to design unique products with its apps and user-friendly software. Then the member manufactures them for their own use or to sell in its online store with their Wifi-enabled plug-and-play 3D printers or a cloud printing service.

Will every home have a 3D printer? Will we lose our need of the manufacturing industry? Industry expert Terry Wohlers doesn’t think so. He says home devices won’t have the capability to make what the consumer wants with the desired color, surface finish, and texture in the material with the right mechanical properties. He says most people aren’t really interested in working with data and manufacturing processes or doing the required cleaning up and finishing of the things they make.

Wohlers thinks the real game changer will be a kids’ version—inexpensive, simple and safe. Kids play. They touch things. They imagine and make things. The kids who now spend hours with Lego bricks will be using their 3D printers to make real model cars, action figures, fashion dolls, guitars, puzzles, and amazing things we as adults can’t predict.

The real payoff of easy 3D “making” is that kids who get hooked on it are the ideal future manufacturing workforce we are so worried about finding. It wouldn’t be a bad idea for companies that want to cultivate talent to donate new 3D printers and software to math, science, and vocational training classrooms and make it possible for their engineers and designers to visit schools and help out. It would be a lot better than complaining about not being able to find skilled designers, engineers, and technicians.

Listen to Wired Magazine editor-in-chief and author give his thoughts on the Maker Movement

Read more about 3D printing for kids

Karen Wilhelm has worked in the manufacturing industry for 25 years, and blogs at Lean Reflections, which has been named as one of the top ten lean blogs on the web.