Design-Build & Liquid Cooling: Powering the Next Generation of Data Centers

The world’s appetite for data is surging at an unprecedented pace. Artificial intelligence, machine learning, and cloud-based applications demand powerful, dense computing environments that can operate around the clock. At the same time, sustainability goals and rising energy costs challenge data center operators to manage heat and energy consumption more efficiently than ever.

Traditional air-cooling systems have been stretched to their limits, constrained by finite facility footprints as well as lower cooling capacity and energy efficiency. In turn, these limitations have curbed rack densities, server lifespans, and chip performance, directly affecting data center owners’ service capacity and quality for customers. Ten years ago, these problems were known but manageable; today, realities such as much more powerful chips, widespread AI, a more mature e-commerce market, a vastly larger digital industrial landscape, and higher utility costs all contribute to an urgent need for improvement. Transitioning the data center industry from air cooling to liquid cooling is the key to solving these challenges. This transition will demand new ways of designing and engineering data centers.

Enter Gray and Valvoline, two companies whose expertise naturally converges at this critical intersection of infrastructure and innovation.

Gray has earned global recognition as a fully integrated design-build leader with a proven track record of delivering complex industrial and mission-critical facilities. Through Gray AES, the company’s professional services offering extends beyond construction to incorporate architecture & engineering, process & utility design, automation & controls, and digital systems integration for customers across its core markets—including data centers and manufacturing. Rounding out Gray’s integrated capabilities are equipment procurement, installation, & commissioning and specialty equipment manufacturing—a truly unique service offering that enables Gray to serve customers’ complete needs from greenfield projects to process upgrades to brownfield retrofits.

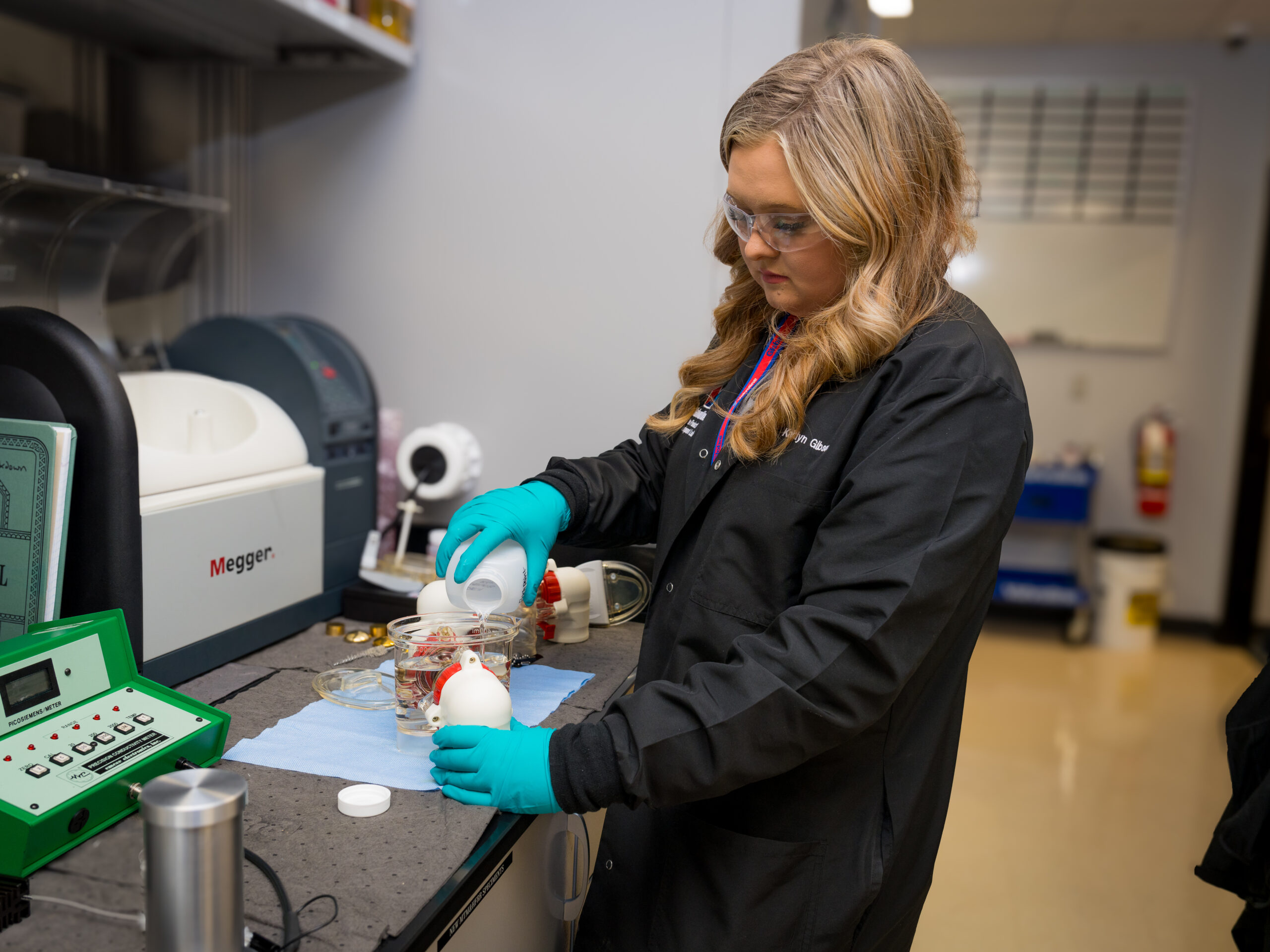

Valvoline is a worldwide innovator in automotive and industrial lubricants, coolants, and thermal management fluids. Drawing on decades of research and laboratory testing, Valvoline has developed specialized fluids that ensure exceptional cooling performance, chemical stability, and long-term reliability in high-performance computing (HPC) environments such as data centers.

Each based in Lexington, KY, these industry leaders have joined forces to usher in the next generation of data center efficiency by pairing the transformative power of liquid cooling technology with the speed and cost savings of design-build project delivery. For the data center industry to fully leverage liquid cooling technology’s advantages, however, owners must modernize their operations with facilities designed specifically to maximize the effectiveness of liquid cooling. The challenge, then, is clear: how best to invest in the first generation of data centers designed for liquid cooling without sacrificing the speed to market demanded by a rapidly expanding industry.

By partnering with an industry leader in liquid cooling technology and an early design-build pioneer with prolific experience in the data center market, cloud service providers can navigate the shift to liquid cooling with speed, clarity, and confidence. Valvoline’s globally-recognized brand, vast experience with OEMs, and extensive performance data on dielectric fluids uniquely position the company to accelerate the adoption of liquid cooling technology in the data center industry. Gray’s legacy as a design-build pioneer and status as a top firm in data center construction provide the credibility and strong knowledge base needed to transform liquid cooling from a concept in a Basis of Design document to a practical, functioning system in a built facility.

Liquid Cooling: A Game-Changer Over Air Cooling

Just as it has long served as the default for cooling people in indoor environments, chilled air has also served as the primary method for cooling computer servers for decades. But as the maximum possible server power density climbs, air-based systems are reaching their practical limits. Sprawling HVAC systems are unable to cool modern servers sufficiently to ensure the 99.99% uptime that data centers require. Forced to compensate for a lack of efficiency with increased operation, legacy air-cooled systems are an inadequate solution amid an industry facing escalating energy costs.

Liquid cooling fundamentally changes the equation for data center cooling. Water, PG25 (a water-glycol mix) and other specialized dielectric fluids can transfer heat away from servers far more efficiently than air; in fact, liquid can be up to 1,200 times more effective at removing heat compared to air cooling. This higher heat transfer capability translates into several critical advantages:

- Improved server performance & energy efficiency

- Increased hardware longevity & reliability

- Higher rack density & scalability

- Less maintenance & downtime

The environmental and financial benefits are equally striking. Facilities with liquid-cooled servers can achieve Power Usage Effectiveness (PUE) ratings as low as 1.02, a significant improvement over the industry average of roughly 1.5–1.6. And because many liquid cooling systems are designed as closed loops, they drastically reduce water consumption. This approach can reduce water usage by as much as 90% compared to conventional cooling towers and evaporative air-cooling. For this reason, liquid-cooled facilities can achieve Water Usage Effectiveness (WUE) values as low as 0.2 L/Kwh, versus an average of roughly 1.8 L/Kwh for typical air-cooled sites.

While new data center builds can more easily implement liquid cooling solutions from the earliest design phase, existing facilities can also be retrofitted for liquid cooling. This technology can be incorporated in a variety of ways to maximize ease of implementation and effectively leverage liquid cooling’s technical benefits:

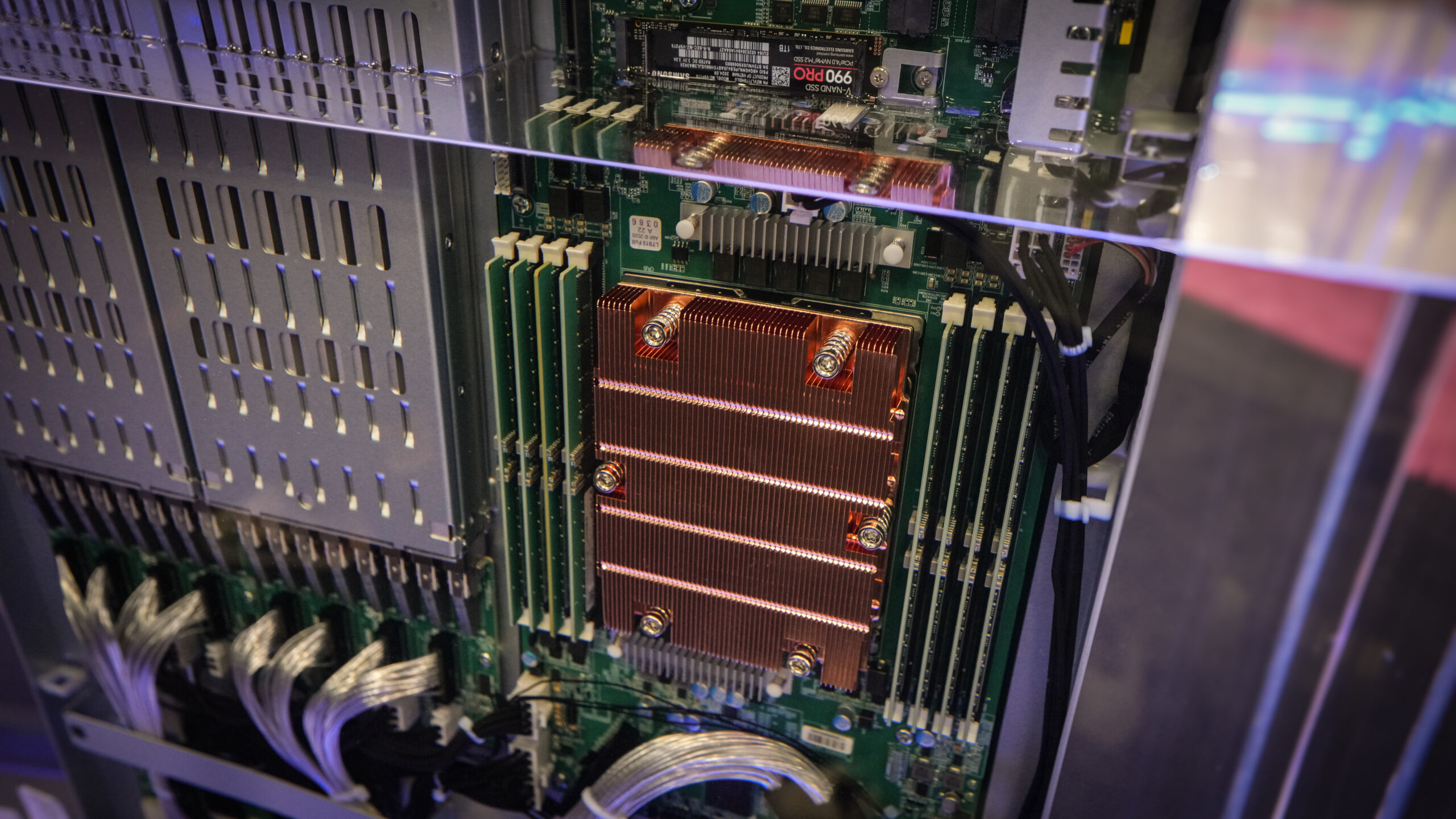

- Direct-to-chip—circulates cooling fluid across a metal plate located directly over the chips, transferring heat through the plate and into the fluid, which carries it away from the server

- Immersion—uses a specialized tank filled with dielectric fluid to safely and completely submerge all server components, providing constant cooling to all parts of the server

- Precision-cooling—delivers targeted cooling to the hottest and most critical server components; similar to direct-to-chip, but with specialized equipment such as spray jets or sealed chassis containing coolant pump systems

- Hybrid—can employ multiple liquid cooling technologies as well as traditional air cooling for heat transfer, allowing for faster, lower-cost implementation ideal for retrofits

Valvoline has developed distinct, specialized formulas for the methods above, providing reliable cooling solutions that meet the highest standards for thermal conductivity, dielectric strength, and chemical compatibility and stability.

Click here to explore Valvoline’s liquid cooling solutions and high-performance thermal management technologies.

Design-Build: The Model Delivery Method for Liquid Cooling Projects

Harnessing the full potential of liquid cooling requires more than simply swapping out air handlers for containment tanks. Whether developing a greenfield facility or retrofitting an existing data center, successful implementation demands precise utility routing, specialized piping, and integration of automation and controls. An integrated design-builder that offers all these capabilities in-house—such as Gray—is ideally positioned to provide a broad base of services and support at the speed data center operators need to keep pace with competitors’ expansion.

Design-build is a project delivery method in which a single entity is responsible for design and construction under one contract with the owner. Unlike design-bid-build or construction management at-risk, in which design and construction are handled through separate agreements, design-build unites the designer and builder from the start of the project as an integrated team. This unified approach allows the team to make coordinated recommendations that align with the owner’s schedule and budget, addressing changes and challenges collectively and consolidating risk with the design-builder rather than the owner. The result is more seamless collaboration, faster decision-making, and greater opportunity for innovation throughout the life of the project.

With Gray AES’ integrated design, engineering, and automation services and Gray’s extensive construction experience in the data center market, owners gain a proven solution to implementation challenges that can be executed at the speed the industry demands.

- Faster delivery

- Enhanced collaboration

- Greater flexibility & adaptability

- Stronger cost controls & risk mitigation

- Optimized for innovation

For operators considering liquid cooling, these benefits amount to faster deployment, more predictable costs, and a more reliable outcome than a multi-contract approach.

Click here to learn more about Gray’s experience delivering integrated services for the data center industry.

Why Valvoline & Gray Are the Ideal Team to Lead

While other firms may offer pieces of the puzzle, the Gray | Valvoline partnership provides a complete solution that few can match.

With a nearly 160-year legacy of chemical innovation and performance testing, Valvoline’s advanced cooling fluids are trusted worldwide in applications where thermal stability and dielectric safety are paramount. Moreover, its global R&D and supply chain ensure consistent quality and scalability for data center operators of any size.

“Unlike firms limited to a single project phase, Gray offers comprehensive, in-house expertise through its family of companies,” says Gray, Inc. President & CEO Stephen Gray. “These include Gray AES for design, engineering, and automation solutions; Gray Construction for experienced project management; NexGen Contracting for craft labor; and Anderson Dahlen for custom equipment manufacturing. For data center owners, this means a single trusted partner for all critical scopes of an expansion or retrofit project.”

This approach ensures fully integrated solutions that span a data center project’s complete needs:

- MEP engineering & process design, including specialized process piping to convey cooling liquids

- Strategic sourcing & procurement of long-lead electrical equipment

- Self-perform construction labor for key trades such as concrete and steel

- Automation & controls to monitor and manage dynamic cooling loads

- Digital systems integration for real-time analytics and predictive maintenance

- Specialty equipment manufacturing to deliver fully integrated, custom-built solutions

- Equipment installation & commissioning to ensure effective startup and operation

A Gray | Valvoline partnership offers a streamlined solution to implementing proven liquid cooling into facilities optimized for these modern systems. Together, our companies deliver the science and execution excellence needed to power the data center industry’s shift to next-generation liquid cooling. Our combined expertise delivers value greater than the sum of its parts, going beyond fluid formulation or facility construction to see the bigger picture and offer complete solutions to the industry’s challenges. With a team that fully understands the science, performance, and equipment needs across a variety of liquid cooling methods, an experienced design-builder can guide data center owners and operators with confidence, delivering facilities that have been purpose-built not simply for liquid cooling, but for the precise methods and formulas our customers need.

A New Standard for Data Center Cooling

The future of data centers is denser, faster, and more sustainable—and liquid cooling delivered through design-build is the key to unlocking it. By combining Valvoline’s world-class cooling fluids with Gray’s integrated design-build services, this partnership is setting a new benchmark for performance and efficiency.

Expect more to come from this innovative partnership, including technical guidance, best practices, and other tools and services designed to help data center owners and operators stay ahead of the curve. With a generation of data center facilities purposely designed for liquid cooling, the industry can reduce operating costs and improve efficiency per IT unit while providing more sustainable services to the customers and communities it serves.

- Category:

- Industry

- Corporate News

- Data Centers